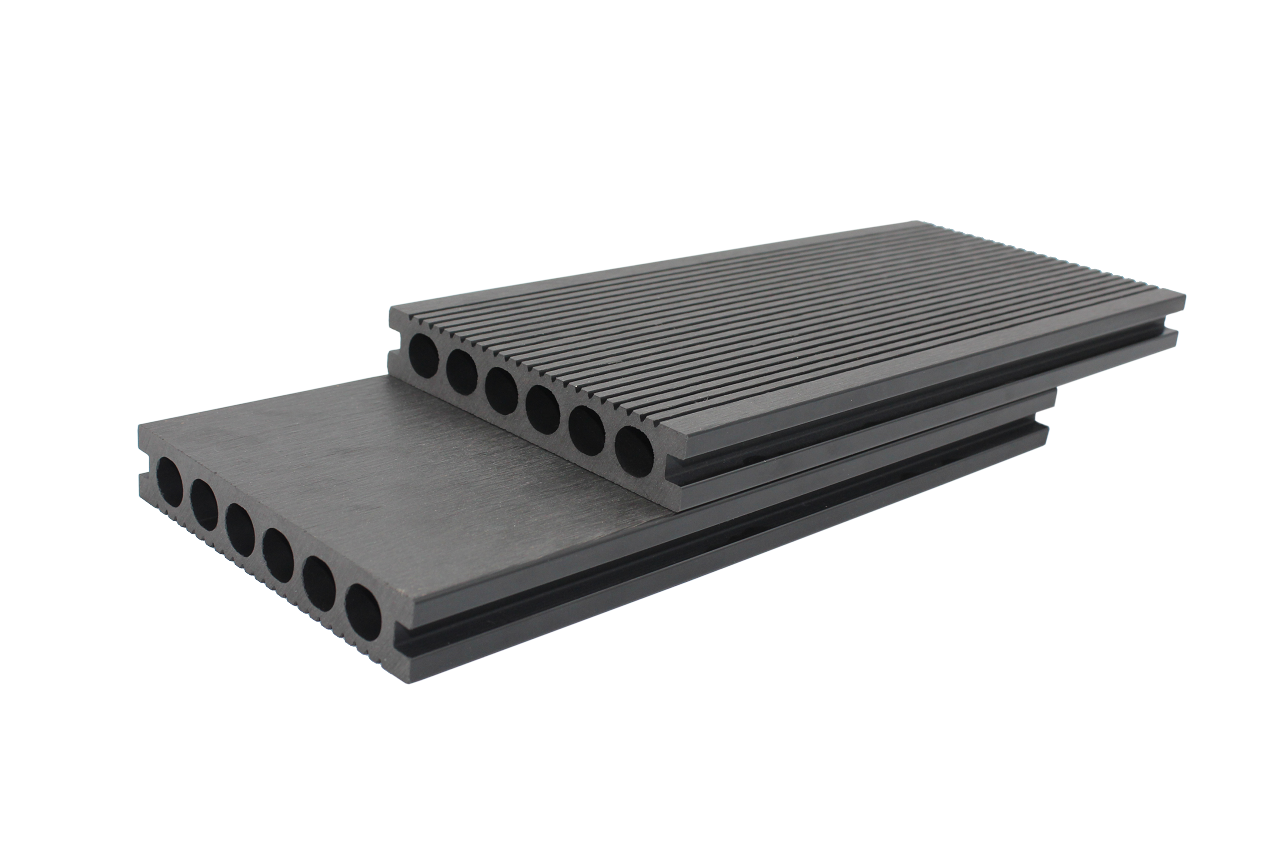

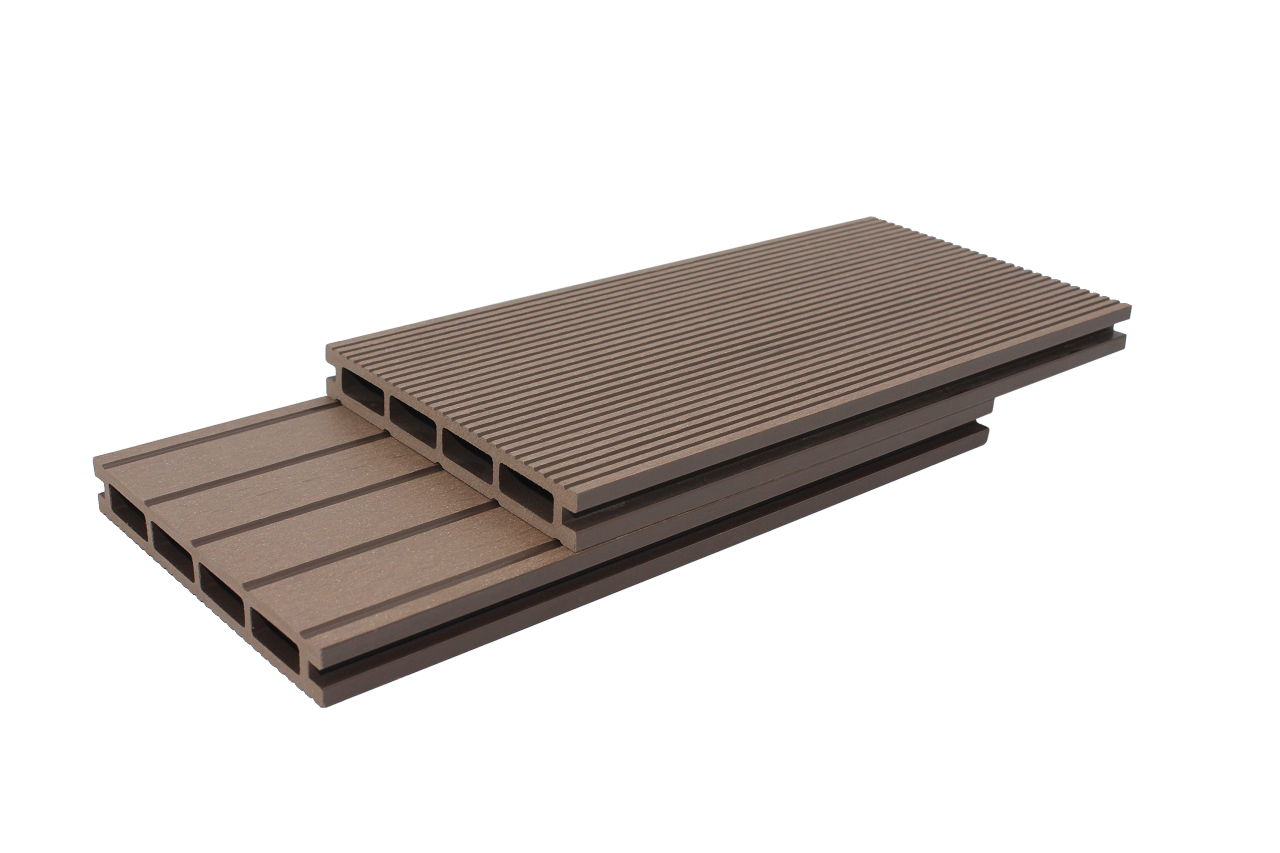

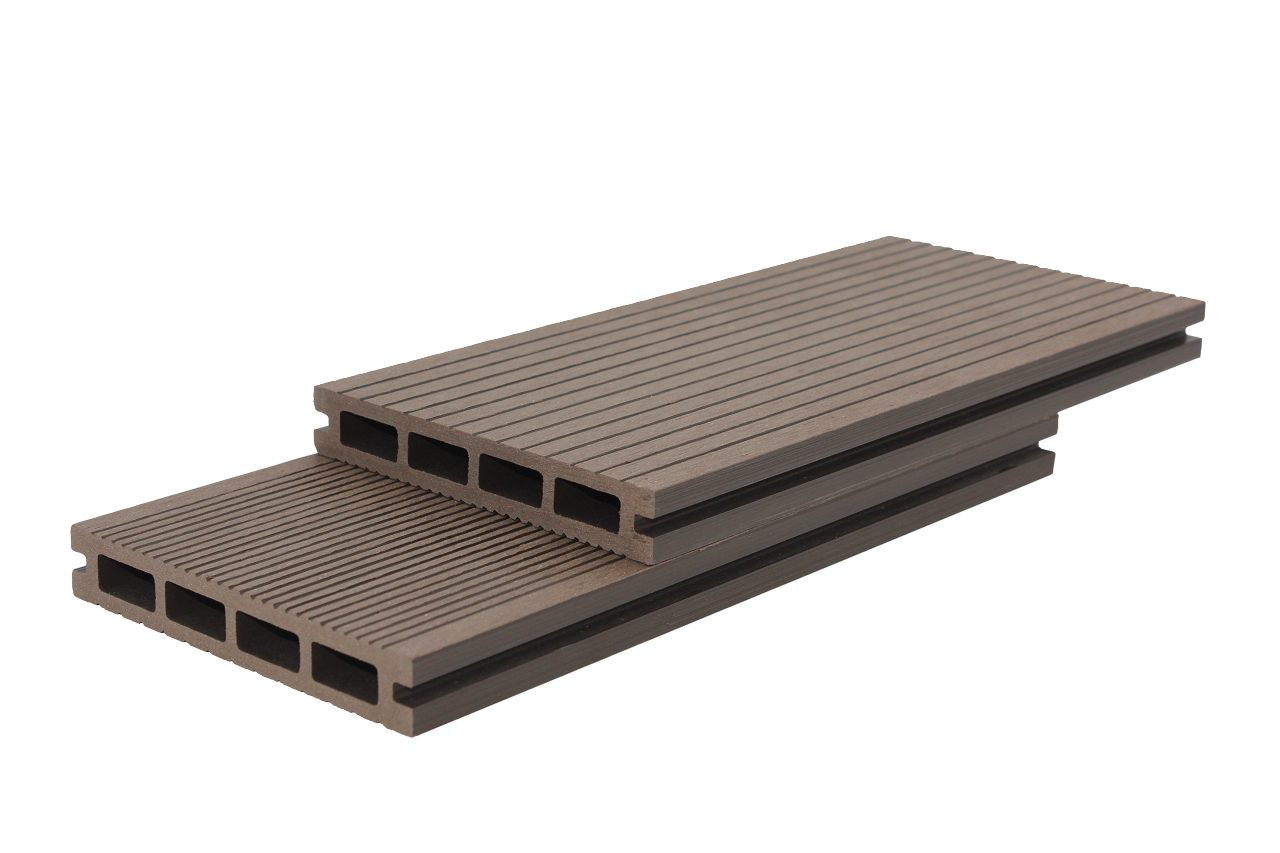

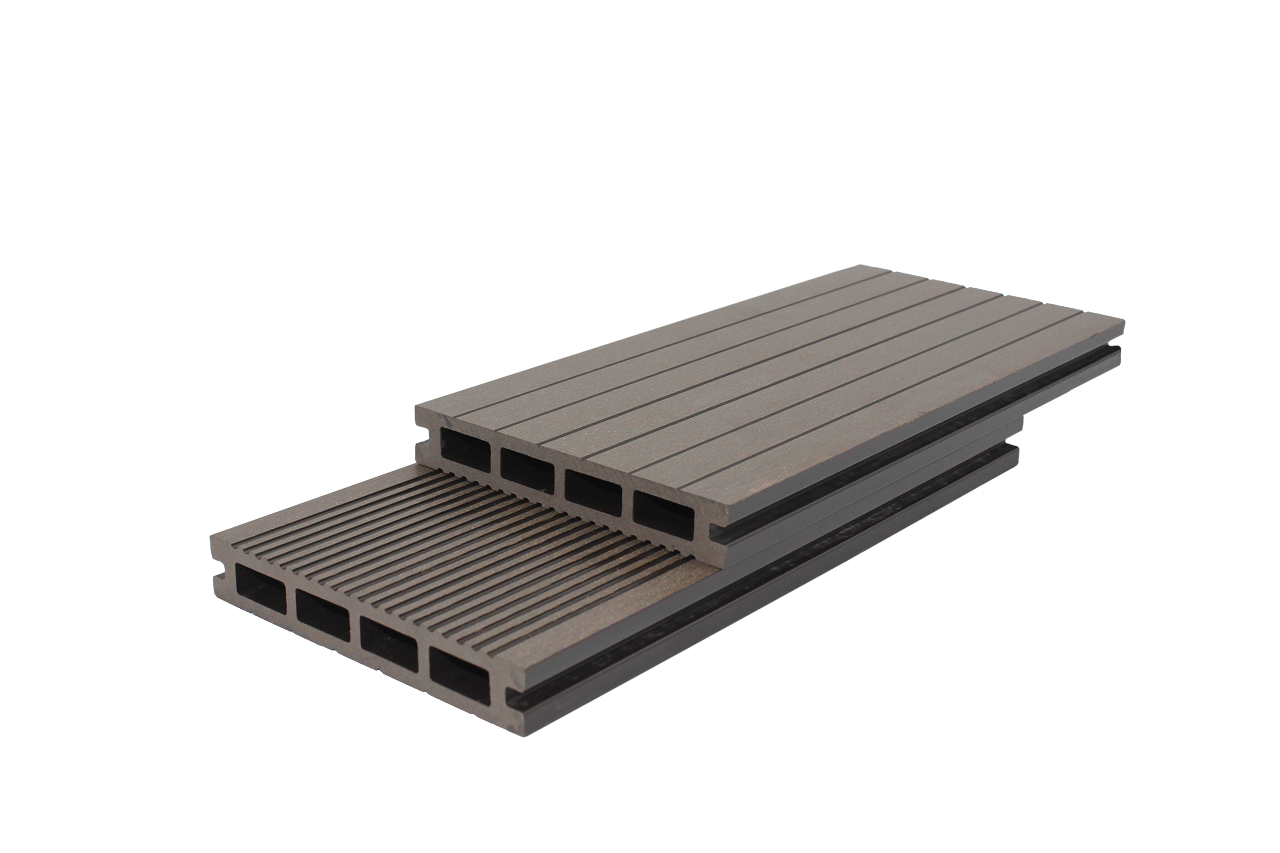

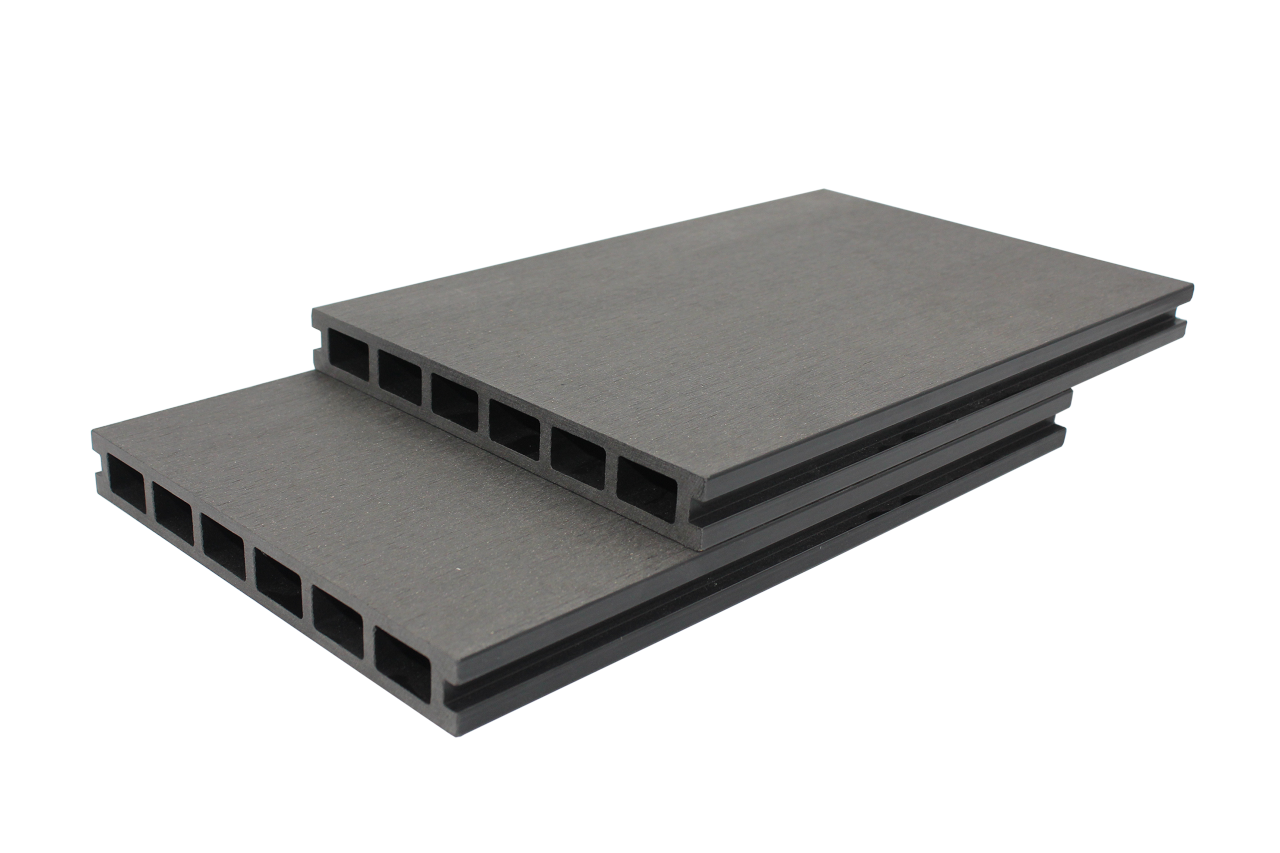

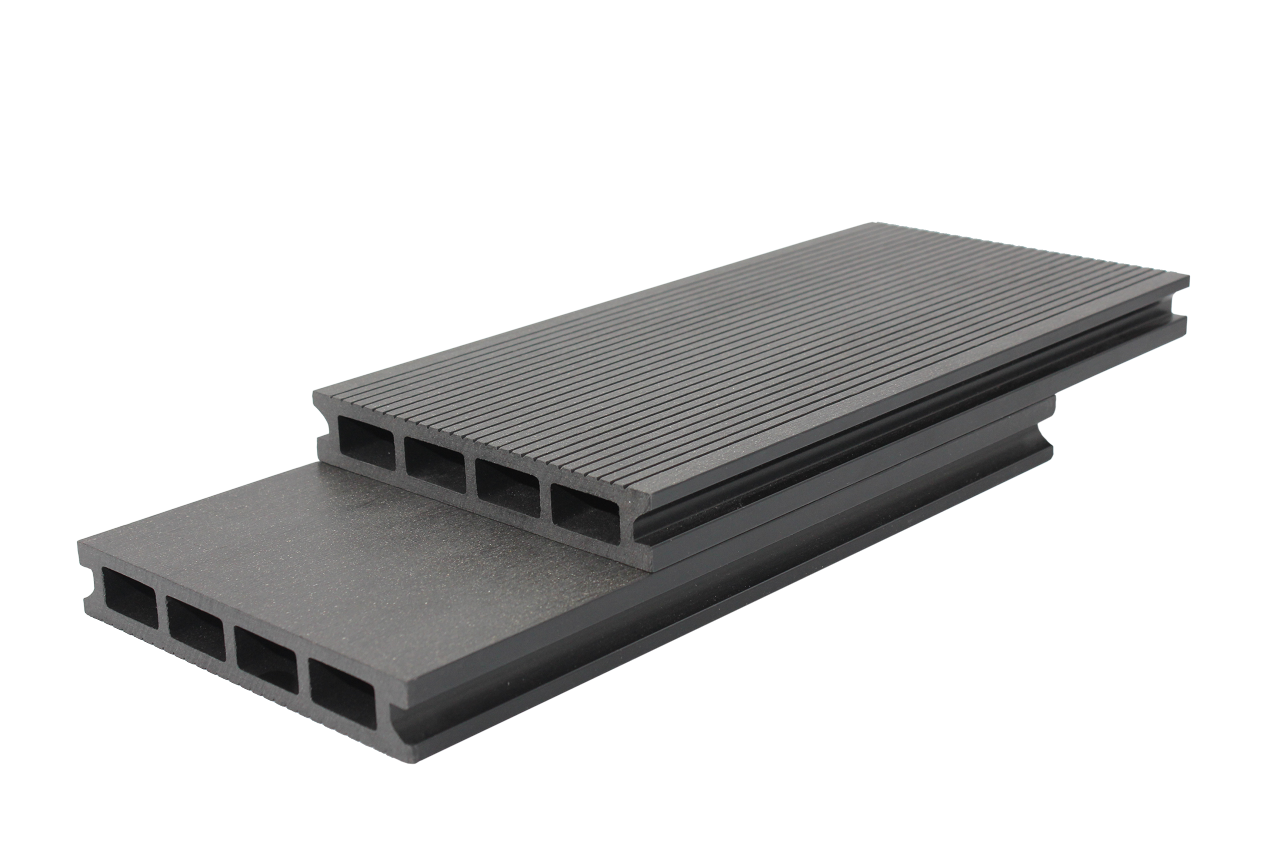

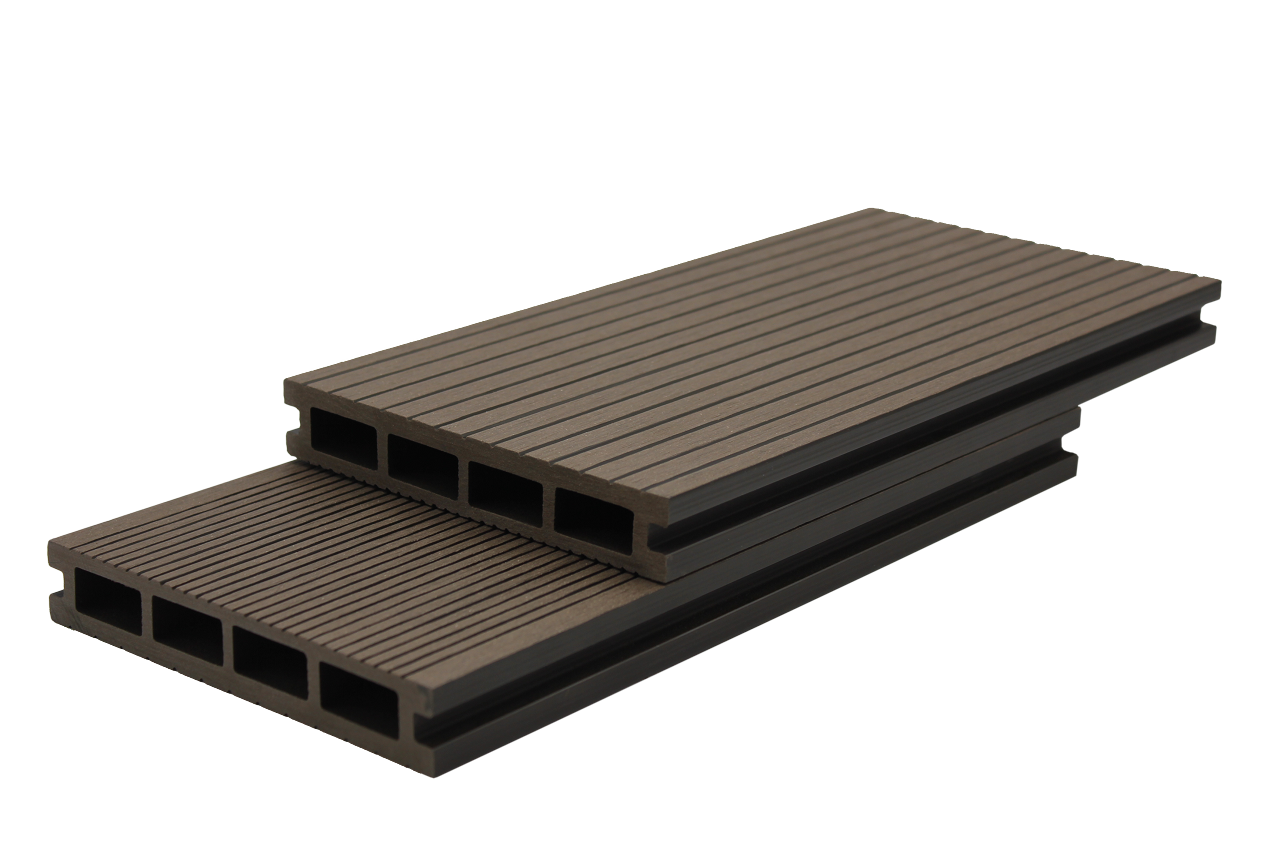

WPC decking(Wood Plastic Composite Decking) - Hollow Composite Decking is a kind of new eco-friendly landscaping material which is produced under high temperature and pressure from the mixture of HDPE and wood fiber.

At present, our products are mainly exported to UK, USA, Germany, Australian, Russia, UAE, Tailand and other global markets. We have set up distributors in Britain, Oman, Ireland, etc. Our hotsell products are availalbe in our local distributors. If you like our products, you can contact our customer service or leave us message, free samples can be provided. We are always looking forward to your call.

Seven Trust Composite Decking/WPC Decking is perfectly suitable for outdoor use:

Low Maintenance and durable: No more paints

Weather-Resistant: No splinters or cracks

Natural: Beautiful appearance of wood

Safe: Anti-slip,eco-friendly

Application:

Seven Trust WPC can be widely used in the garden,square,balcony,terrace,walkway,landscape and so on.

Why Choose Seven Trust WPC Decking?

Firstly, our raw materials are mixed at high temperature. This process is not available in general factories. Its advantage is that the uniform distribution of the mixture will be better. The moisture of the raw materials can be removed quite effectively to make the molecular structure more stable and tight. The expansion coefficient of the product during outdoor use will be less than that of similar products, and the aging speed will be reduced accordingly.

Secondly, HDPE is an important main material of WPC, which directly leads to the advantage of product quality. We use the first grade pe cable leather material. Many factories use PP or secondary material to produce. Under normal natural environment, HDPE has excellent weather resistance. For similar products, PE is resistant to low temperature impact.

Thirdly, the surface treatment of 3D embossed decking that our factory uses 3M soft sanding cloth roller,the general factory is treated with sand belt.3M soft roller treatment has the advantage that the surface 3D effect is real,and the peeling effect is good, the sand belt is peeled rough surface, strong plastic, the advantage is low processing cost.

Installation Instructions Video:https://shanghaiwpc.com/video/wpc-decking-installation.html

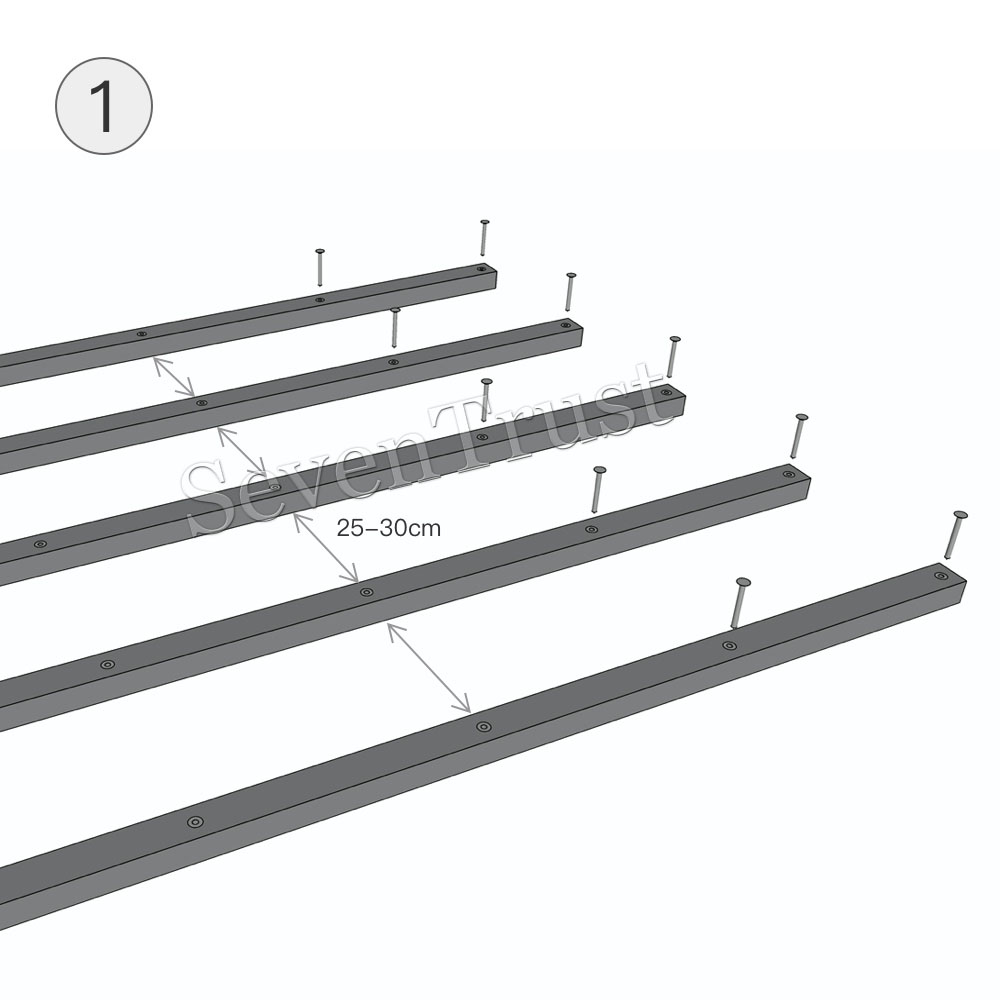

1. Before installing the joist, make sure the ground is flat and solid so that the joist can be fastened tightly on the ground. Then dig holes with percussion drill in the deck area and bury the plastic tube into the holes.

2. Take the buried expansion tube as center, put the joist stably on the center line, pierce the joist with pistol drill and nail the screw into the expansion tube.

3. Nail the expansion screw into the top of the vertical joint of two joists.

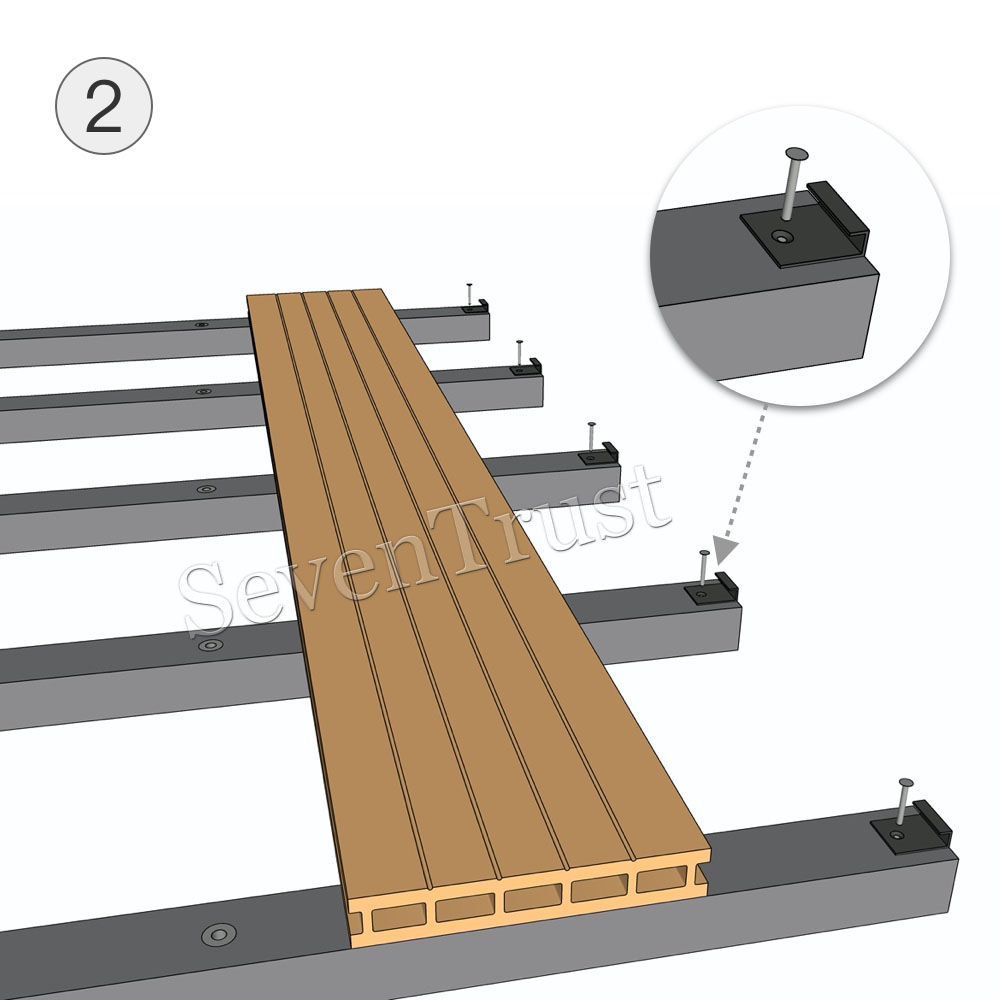

4. Put flat the deck along the vertical direction of joists, the ending deck can be fixed on the joist with screw to make sure the accuracy of it being the base floor for other decks.

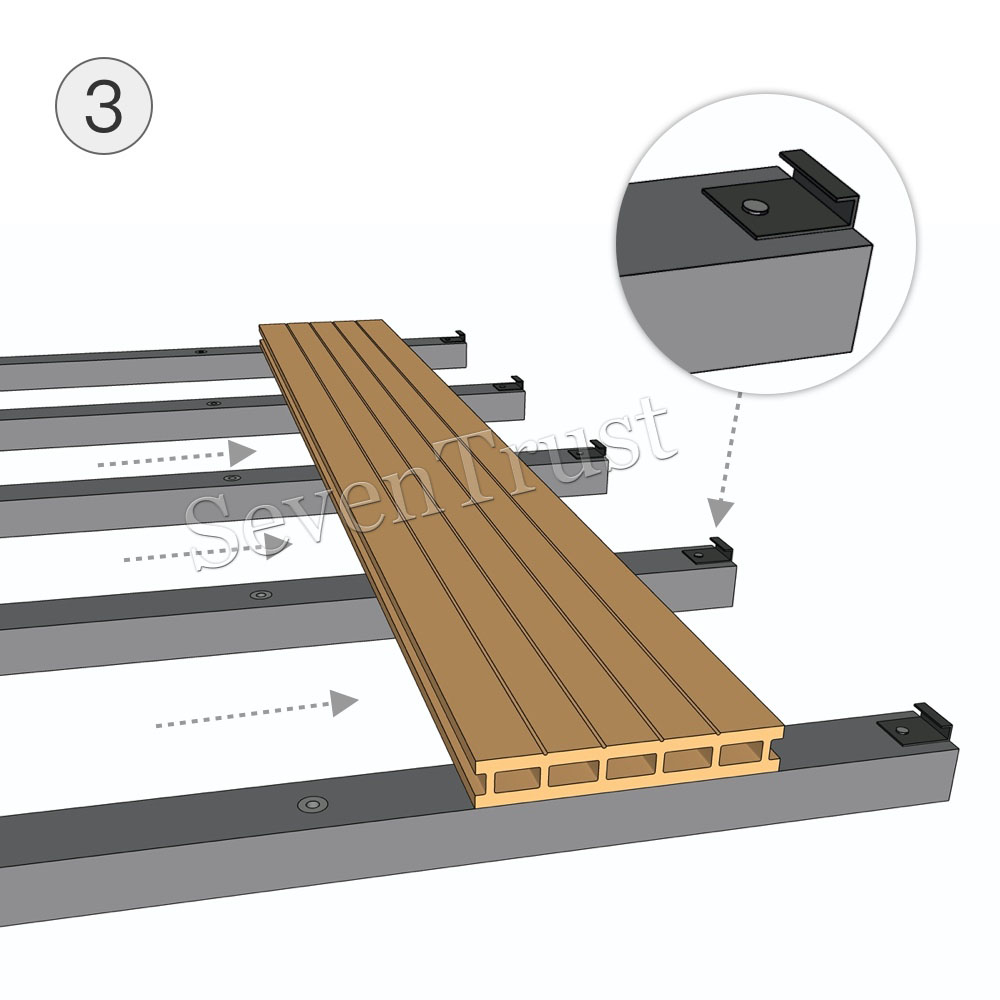

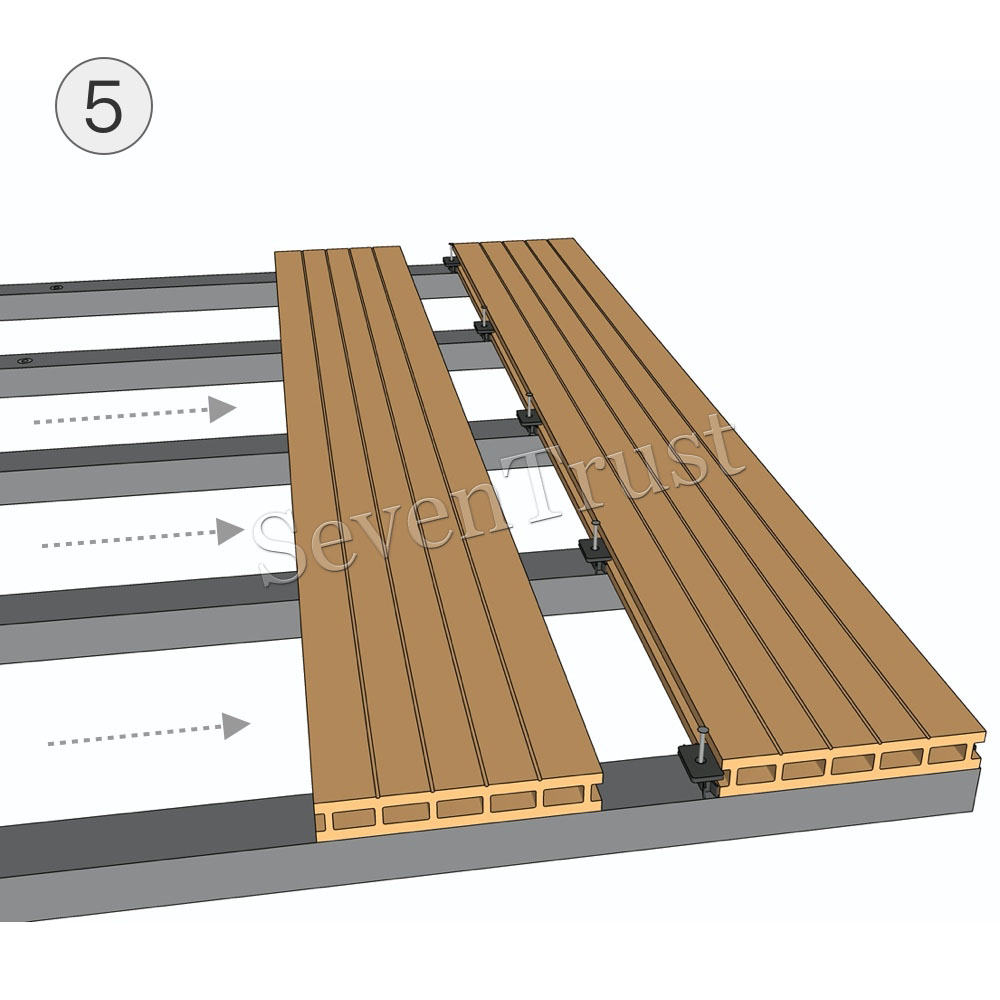

5. Install clips on the other side of the first deck, and start installing decks in order.

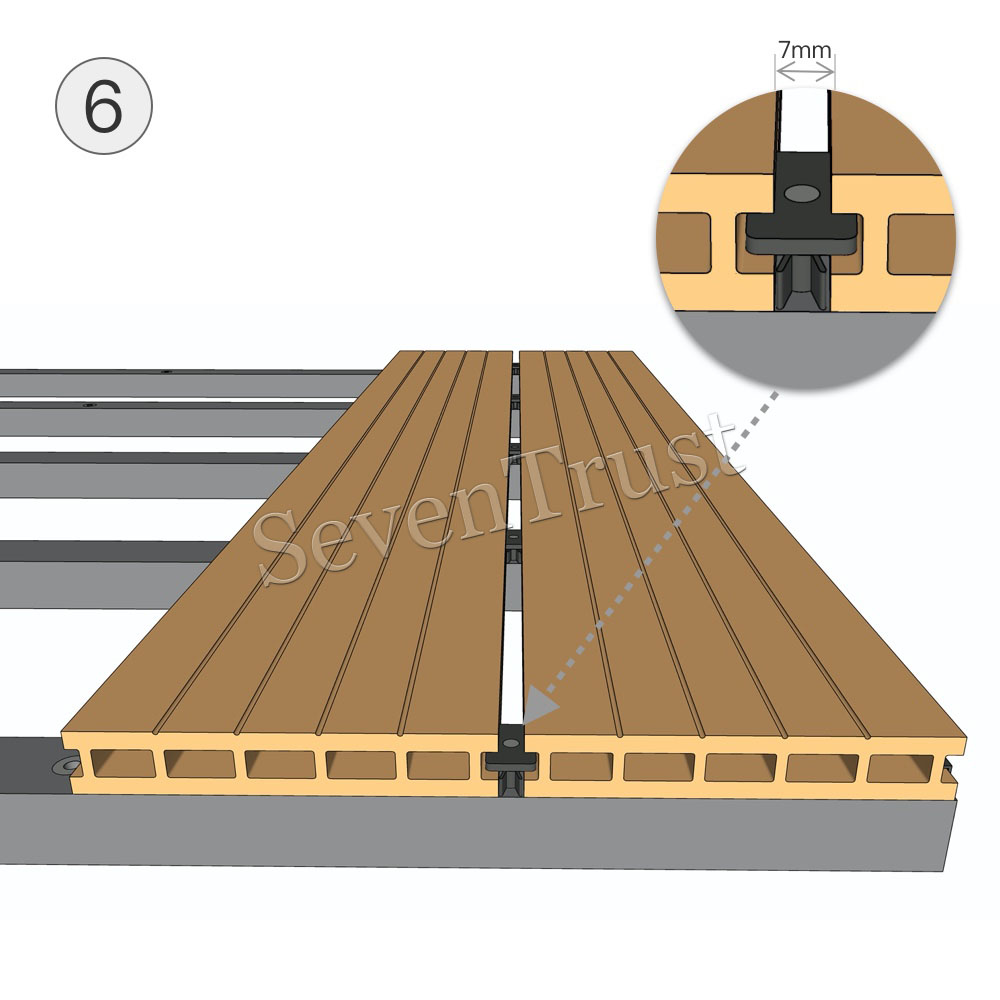

6. Install 2 joists in the longitudinal joint of two decks.

7. To avoid possible deformation caused by temperature change, joists can not be tied too closely.

8. Outside the last deck, use the same installation method as that of the first deck, install edge seal and terminal sealing board.