Insulation function of plastic wood materials

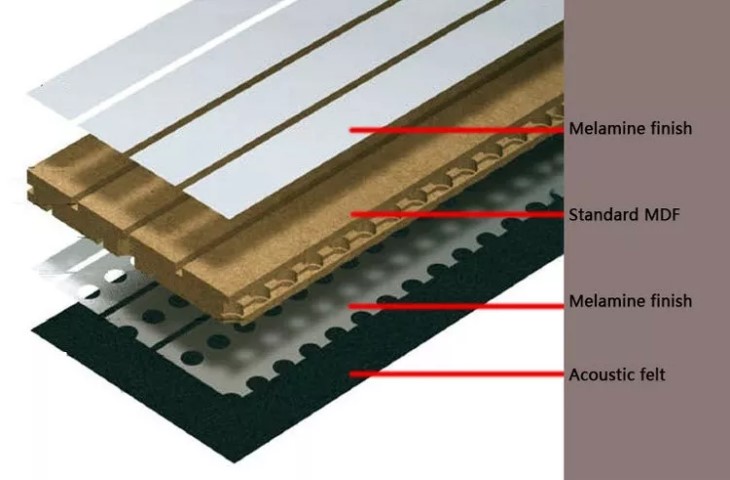

Friday, May 26, 2023It is understood that the energy loss of Chinese housing is roughly 50% for walls, about 10% for roofs, about 25% for doors and windows, and about 15% for basements and floors. It can be seen that the selection of wall insulation materials is the main way to achieve indoor insulation. way. Wood-plastic insulation wallboards are made of thermoplastics such as polyethylene, polypropylene, polyvinyl chloride and their copolymers, and wood powder such as wood powder, plant straw powder, and plant seed shells. , Composite board formed by filling various insulation materials into a hollow board by pressing method. It is a new type of wall decoration material that integrates decoration, heat preservation, sound insulation and fire prevention. Its heat preservation effect is 7 degrees higher than that of ordinary boards and 10 degrees higher than that of paint, which can reduce the loss of indoor temperature, so that in the cold winter Create a warm home environment.

Plastic-wood wall panels are currently the mainstream thermal insulation materials in the world. They are mostly used for architectural decoration such as walls, doors, windows, and exterior walls, which shows their thermal insulation performance. Through the application of environmentally friendly thermal insulation materials in the product, in addition to the thermal insulation effect in winter, the plastic wood wall panel can also play a thermal insulation effect in summer. It is suitable for the south and the north, and meets our desired warm winter and cool summer requirements. And the sound insulation effect reaches 29 decibels.

The outer layer of the plastic wood board is surrounded by a closed inner cavity of the plastic wood wall panel, and various thermal insulation materials are added in the middle to make a self-insulating plastic wood board. This kind of plastic wood board can be applied to the outer wall of the steel structure to realize the thermal insulation performance of the steel structure itself. At the same time, it also reduces the weight of the building itself and saves materials. Nowadays, many kinds of exterior wall systems can be used in steel structures. The self-insulation of plastic wood panels is applied to steel structures, which not only plays the role of exterior walls, but also no longer needs to be used as a separate insulation layer. However, since the plastic-wood self-insulation board is a new exterior wall panel, and the steel-frame plastic-wood exterior wall self-insulation system is a new exterior wall system, there has been no actual research and application before, and a lot of work still needs to be carried out. For example, optimize the formula of plastic-wood materials and strengthen the production process to reduce production costs and improve its durability; optimize the structure of the board to improve its thermal insulation, etc.

The following focuses on some problems that need to be solved in the node structure and construction of the self-insulation system of the plastic-wood exterior wall of the steel structure.

(1) Considering various factors such as wall strength, construction speed, and construction convenience, determine the cross-sectional form of the plastic-wood self-insulation board.

(2) After determining the cross-sectional form of the plastic wood panel, the connection method between the panels should also be determined. According to the requirements of the facade form of the building, the plastic-wood panels can be arranged in two ways: horizontal and vertical, but the joint mode of the vertical joint and the joint mode of the transverse joint need further design.

(3) Determine the node structure of the self-insulation system of the steel structure wood-plastic exterior wall panel. The joint structure of the plastic wood panel wall, such as the joint structure of the plate and the column, the joint structure of the plate and the beam, the connection structure of the plate and the roof panel, the connection structure of the positive and negative corners of the plate and the frame beam and column, the joint structure of the upper and lower sides of the door and window, The parapet, cornice and frame beam-column connection structure must be designed. However, there are no detailed specifications for the connection mode between the plastic-wood exterior wall panels and the connection mode between the plastic-wood exterior wall panels and the steel frame structure, and the atlas can be used for reference, so we can only refer to the domestic and foreign steel structure exterior wall panels. The joint structure and connection method of the WPC exterior wall are determined based on the relevant data of the node structure and the connection method. At the same time, the material properties of the WPC panel itself must be considered to determine the node structure and connection method suitable for the WPC panel and the steel structure.

Determine the construction method of the self-insulation system of the steel structure wood-plastic exterior wall panels. In the on-site construction of steel structures, the construction of wall panels is very important. Such as the setting out of the wall, the lifting and installation of the plastic wood board, the installation of doors and windows, quality inspection, etc. The construction method of the steel structure plastic wood self-insulation wall system has no specific operating specifications in our country. We can only refer to the relevant specifications and construction methods to study the construction method of the steel frame plastic wood exterior wall self-insulation system and obtain It is very meaningful to propose specific construction methods for use in actual projects to guide on-site construction.