How to choose Wooden Plastic Floor

Wednesday, June 14, 2023During the decoration, buying decoration materials is a very important link. Plastic flooring is gradually accepted and adopted in decoration due to its good practical performance.

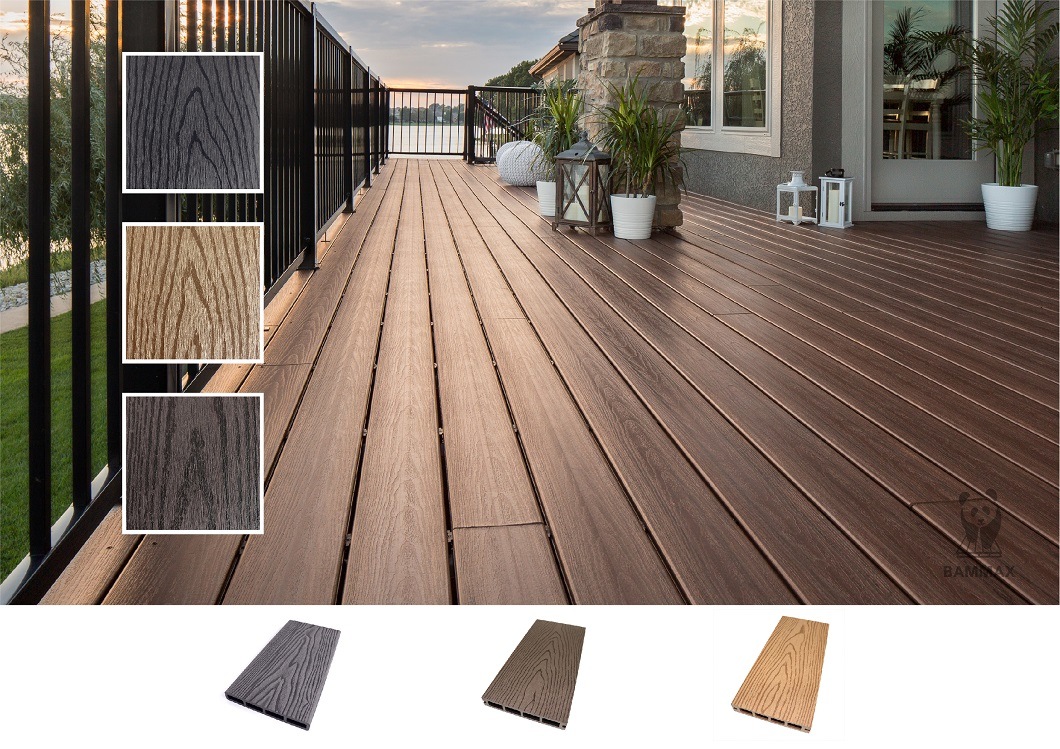

Concept analysis: Plastic wood flooring is a high -tech green environmental protection material mainly made of wood as the basic material and thermoplastic polymer material and processing assistant.

Advantages analysis: Plastic wood flooring has the performance and characteristics of wood and plastic. It is a new type of environmentally friendly polymer composite material that can replace wood and plastic, which can be used like ordinary wood. At the same time, plastic wood flooring has the wooden texture of wood and the water resistance and anticorrosive properties of plastic, making it a well -outdoor waterproof and anti -corrosion building material.

For private owners, plastic flooring can be used for garden floor paving, balcony paving, etc. However, industry insiders have pointed out that there will also be misunderstandings in the purchase of plastic wood flooring, so that consumers can clearly buy it.

Misunderstanding 1: Buy and decorate the construction materials, you will first want to ask whether plastic wood materials are environmentally friendly

Many consumers think that the plastic wood floor made made of new plastic wood composite materials contains a large amount of methanol toxic substances. In fact, this is the case. You can use it safely. Ruijing Hongxing’s products are tested and certified by professional institutions, which meets national environmental protection standards.

Misunderstanding 2: The plain board is plastic wood flooring

The plain board is a plain board, but don’t think it is a genuine plastic wood flooring. After buying a plain board, and then buying the paint and polishing, it seems to save a lot of costs, but the pollution problems caused by the materials such as paint are far from saving money. The real plastic flooring is done by the manufacturer through mechanized and highly active production lines to avoid pollution substances and make the product more environmentally friendly.

Misunderstanding 3: Plastic wood flooring is not packed

Who will I find after buying plastic wood flooring? In fact, good plastic wood flooring manufacturers such as quality and word of mouth usually have professional installation staff to help guide the installation, selling, paving, and after -sales one -stop services. It is not the same family who only sells for the installation, or the sale and installation. At this time, you must be cautious. In case of quality and other problems, it is easy to cause the phenomenon of kicking the ball.

Misunderstanding 4: Add large core board when laying

Light -paved plastic wood flooring is not enough. In order to have a better sense of foot, many people will spread a large core plate on the keel. To be ignored, the quality of the large core plates is generally poor, and the inferior large core plates have a great impact on the pavement effect of plastic wood flooring. Therefore, if you insist on adding a large core board, you must choose the quality of reliable quality.

At the same time, it is also very important to choose a good plastic wooden manufacturer. Now the Internet is highly developed. Most customers judge by browsing products, pictures and customer evaluations through web products when choosing plastic wood manufacturers. For this situation, we recommend that customers can take the following measures to verify:

1.It can be required to issue relevant company certificates (such as business license, taxpayer registration certificate, etc.)

2.Inquire the enterprise registration information of plastic wood manufacturers through the Internet

3.Whether it is a real manufacturer, whether the company name displayed online is consistent with the name of the manufacturer named a contract (receiving company, actual supply)

4.Can I issue the corresponding product testing report, the certificate of the factory, and whether the company used is consistent with the Internet

5.If possible, you can inspect the production scale, supply capacity and quality management process of plastic wood manufacturers