Development trend of wood plastic full cladding technology

Thursday, April 27, 2023Wood-plastic composite material full-wrapping technology is one of the development trends of wood-plastic composite material. The full-wrapping technology of wood-plastic composite materials is not only to cover and wrap a layer of functional materials on the surface of wood-plastic composite materials to make them have higher strength, wear resistance, anti-aging performance and flame-retardant and corrosion-resistant properties, but also to improve the performance of wood-plastic composite materials. The process link of product practicability and surface aesthetics. The use of full-wrap technology has expanded the application fields and product categories of wood-plastic composite materials.

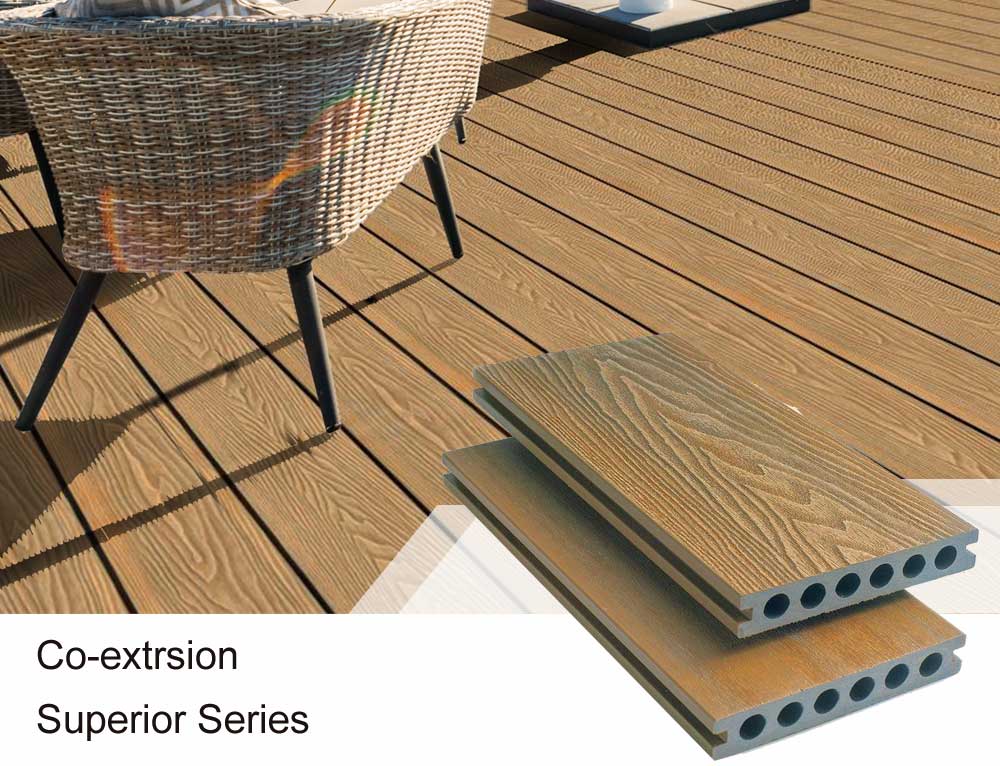

Wood-plastic full-covering technology combined with wood-plastic post-treatment technology can carry out high-performance new-generation wood-plastic composite materials for belt sanding treatment, embossing treatment, water transfer printing and heat transfer printing, UV printing and solid wood veneer composite treatment, etc. . These technologies greatly improve the material properties of wood-plastic composite materials, and at the same time greatly improve the aesthetics and added value of wood-plastic composite materials. Through different surface treatment methods, different styles of surface effects can be developed to meet the requirements of customers in different regions, different cultures and aesthetic requirements. The wood-plastic composite material has a good wood feel and natural texture on the surface, which makes it have a unique product style and aesthetic style.

In recent years, as an advanced technical process, wood-plastic coated co-extrusion has been widely adopted by European and American countries. With the maturation of surface materials and the gradual improvement of co-extrusion technology, there are more and more co-extruded wood-plastic products in the European and American markets. Not only It is the traditional plastic-wood doors and windows, handrails, and fences that use plastic-wood co-extrusion. Even new-type floors, fences, exterior wall panels, and templates are increasingly using plastic-wood co-extrusion. It can be said that plastic-wood co-extrusion has become a plastic-wood co-extrusion. The main trend of wood products. For example, the wood-plastic material produced by PVC series wood-plastic special coating co-extrusion material has many advantages such as realistic wood grain effect, super high weather resistance, excellent wear resistance and scratch resistance. Due to the use of micro-foaming technology, the density can be adjusted according to needs. The paving rate of PVC series wood-plastic materials is higher than that of PE wood-plastic materials, and the cost is more advantageous. It has been widely recognized by the majority of plastic-wood enterprises. After a long period of production tracking, some common problems and solutions in the production process of plastic-wood cladding co-extrusion have been carefully and detailedly summarized and hoped to be discussed by industry colleagues.

The wood-plastic composite material industry is a multi-directional, long-span, and specialized emerging industry. The development of the industry is in line with the policy orientation of the country’s low-carbon economy, and it is a new material industry supported by the state. With the support and development of the country, the industry level has approached the international advanced level. At present, wood-plastic materials involve several categories such as structure, decoration, packaging and special profiles, covering almost all the current application fields of wood, plastic, metal, aluminum alloy and other materials. The annual output value is increasing year by year, and the market potential is huge. Generally speaking, the development of wood-plastic composite material industry conforms to the characteristics of low-carbon circular economy and is the highlight of low-carbon economy. With the awareness of environmental protection deeply rooted in the hearts of the people, resource recycling and material recycling have become the core and mainstream trend of economic development. The development of wood-plastic composite materials will have a profound impact on the national economy and environmental protection. And at present, the amount of white waste produced in my country is still huge every year. Wood-plastic composite materials are still in their infancy in China at this stage, and there is still huge room for growth. A larger market for plastic-wood composite materials is waiting to be developed and utilized, and the development prospects are promising.