What is the difference between plastic wood floor and ordinary floor?

Friday, August 4, 2023The installation of the floor will bring some good experiences and feelings to the entire courtyard environment. Plastic wood flooring is the choice of many consumers. So what are the advantages and disadvantages of plastic wood flooring? What are the differences between it and ordinary floors? Woolen cloth?

Many people choose ordinary wooden flooring, because this kind of board has natural texture and is more wear-resistant, but wooden flooring also has great disadvantages during use. For example, this kind of board is easily affected by the humid environment after installation. The board will be moldy and deformed in a humid environment, so people need to replace and maintain it regularly, and these problems can be avoided by using plastic wood flooring.

The advantages of plastic wood flooring

1.Its environmental protection is relatively strong, it will not contain chemical components, some anti-corrosion properties are also very high, it does not contain harmful substances such as formaldehyde, and it will not pollute the air. The most important thing is that it can be recycled. Function.

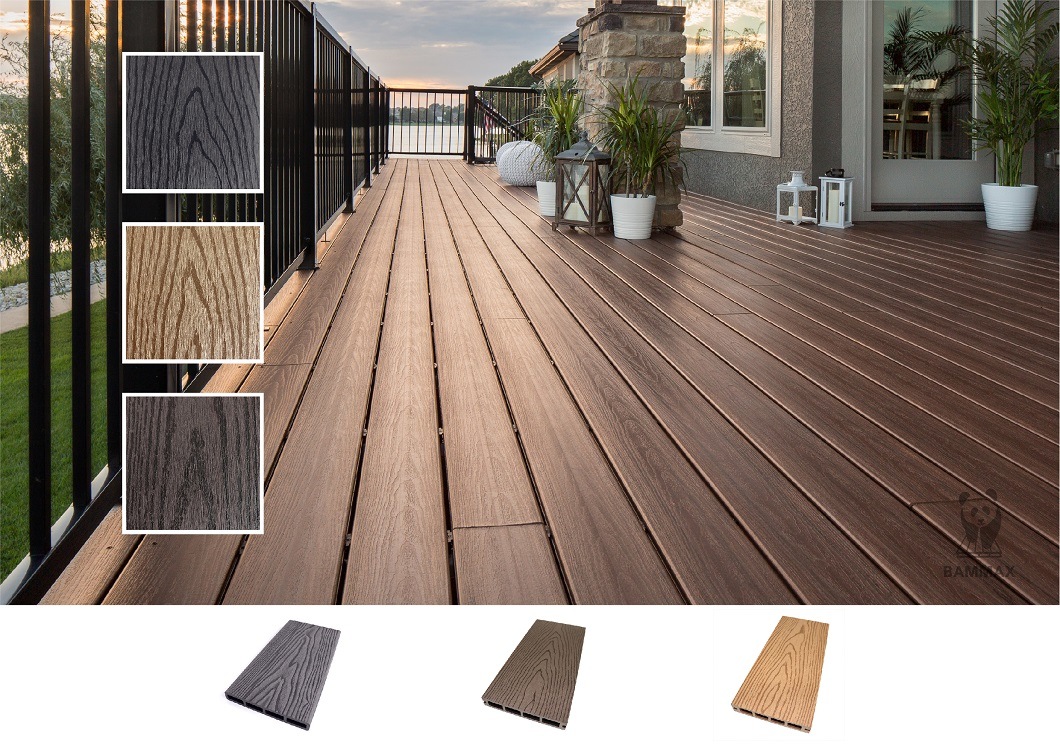

2.The appearance of plastic wood flooring is also relatively good-looking. It generally does not have knots, cracks and deformation. The colors of products made of this material are also different, and its surface is not There will be a second painting, so it will not fade after a long time of use.

3.Plastic wood flooring has high-strength adhesiveness, so it will not crack. Its wear resistance and anti-slip are also very good. Generally, the absorption is relatively small, so this material is used outdoors more. It also has the function of anti-ultraviolet rays, so it has flame retardancy.

4.Plastic wood material is a new type of environmentally friendly material. During the processing and production of this kind of board, components such as recycled plastics and fiberboard will be added, so that the board made in this way is more stable and reliable during use.

5.The main material of plastic wood flooring is plastic and wood powder or bamboo powder. After adding additives and mixing at high speed, it is granulated, and then extruded by an extruder to form a material. After grinding, embossing, etc. This kind of floor can be used for outdoor platforms such as gardens and villas. It is waterproof, flame-retardant, and non-slip. It has good processing performance and a warranty of 8-15 years.

6.During the processing of plastic wood flooring, raw materials such as wood powder and auxiliary agents will also be used, but during the selection of raw materials, the environmental protection of raw materials will be paid attention to, so as to achieve better application effects and avoid using boards Harmful substances such as formaldehyde are produced at times, which reduces the harm to the human body, which also meets modern environmental protection requirements.