What you should know about wood-plastic flooring before buying

Wednesday, June 28, 2023Since garden floors are exposed to the outside, they are easily affected by the weather. So the wooden floor will deteriorate, which is a natural phenomenon. If you’re using wood-plastic composite for your garden floor, then you don’t have to worry too much about mold and rot from the elements.

If you have a wooden floor installed in your yard, you will need to perform regular maintenance on it in order to prevent it from mold and rot. This not only means that you need to spend extra time and labor costs, but also need to spend extra money.

WPC flooring is one of the best alternatives to traditional wood flooring. If you’re looking for a durable, low-maintenance floor finish that requires no maintenance, WPC may be the floor for you.

What is plastic wood flooring?

PVC floor

Often referred to as plastic lumber. This decorative wood is made from recycled plastic or new materials. It is usually single resin polyethylene (HDPE and LPDE), polystyrene or polyvinyl chloride (PVC). PVC plastic flooring appeared in the building materials market in the late 1980s. And are similar in size to traditional lumber.

WPC floor

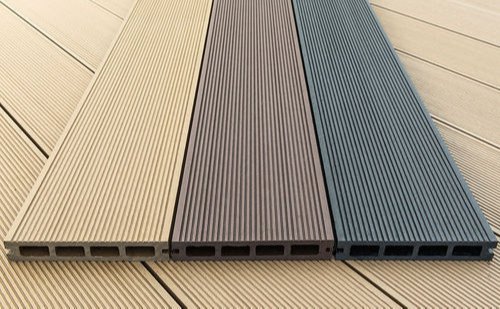

Wood-plastic flooring is different from plastic flooring. It is made of recycled plastic and wood fibers. In many cases, substantially all of the plastic used comes from recycled materials. Plastic flooring is just plastic, although it can contain a variety of additives to resist sun damage, scratches, and weather.

In wood-plastic flooring, polypropylene or polyethylene plastic is attached to the wood fibers to form a strong bond. They also help create a textured surface with a color closer to wood than PVC floors. In addition to decorative purposes, wood-plastic flooring has other uses. Includes decking, railings, patio furniture, wall panels and fencing.

WPC flooring is highly durable. Since the wood-plastic material does not absorb water, it is durable. Since it contains no organic matter, it will not rot. Unlike wood, WPC floors do not need to be sanded and re-stained. This means after installing the plastic wood floor. You can enjoy the convenience brought by wood-plastic flooring without spending a lot of time on maintenance.

Co-extruded wood-plastic floor

The co-extruded wood-plastic floor adopts four-sided capping technology, which has better scratch resistance. And excellent resistance to sunlight, stains, mold and bacteria. Excellent resistance to sunlight, stains, mold and bacteria.

Co-extruded wood-plastic flooring benefits from a unique coating formula. Without the unwelcome plastic feel of PVC flooring. At the same time, the unique coating technology gives you an extra tactile experience. It has the characteristics of antistatic, comfortable and soft, and low thermal conductivity.

Advantages and disadvantages of wood-plastic flooring

Advantages of WPC

- Can be molded into many different shapes and sizes

- Waterproof, anti-corrosion, anti-mildew, no need for sealant sealing

- Stain resistant to many chemicals and substances

- Wide variety of colors

- UV resistant, fade resistant

- Free of toxic chemicals such as formaldehyde

- Won’t split or crack

- Excellent insect resistance

- 100% recyclable

- Easy to install

Disadvantages of wood-plastic panels

- Looks a bit plastic up close

- Uniform texture

- Can’t be stained or painted (even if you wanted to)

- Easy to install

Plastic wood flooring can be cut and drilled like wood. No special tools are required. In addition, it can be fixed on the joist with screws like a wooden floor. Therefore, it is possible to install plastic wood flooring with your own hands. Many types of WPC decking come with hidden fasteners. This type of fastening allows the fixings to be hidden under the floor. Leave the top of the floor free of screw heads. It avoids screws and other accessories from affecting the overall beauty of the deck.

In addition, remember to leave 8mm of expansion and contraction space for the expansion of plastic wood flooring. What’s more, read the manufacturer’s installation instructions carefully before installing.

Plastic wood flooring cost

The cost of plastic wood flooring and plastic flooring is higher than that of wood decorative panels. Due to the fact that the maintenance cost of plastic wood flooring is very low compared with wood flooring. And has a longer service life. So in the long run, it is more appropriate to choose plastic wood flooring.

Accurately compare the costs of wood floors. Consider the cost of wood floors that require regular refinishing. In most cases, wood floors should be restained or sealed every two to three years. Material costs add up, as does labor or time if you do it yourself.